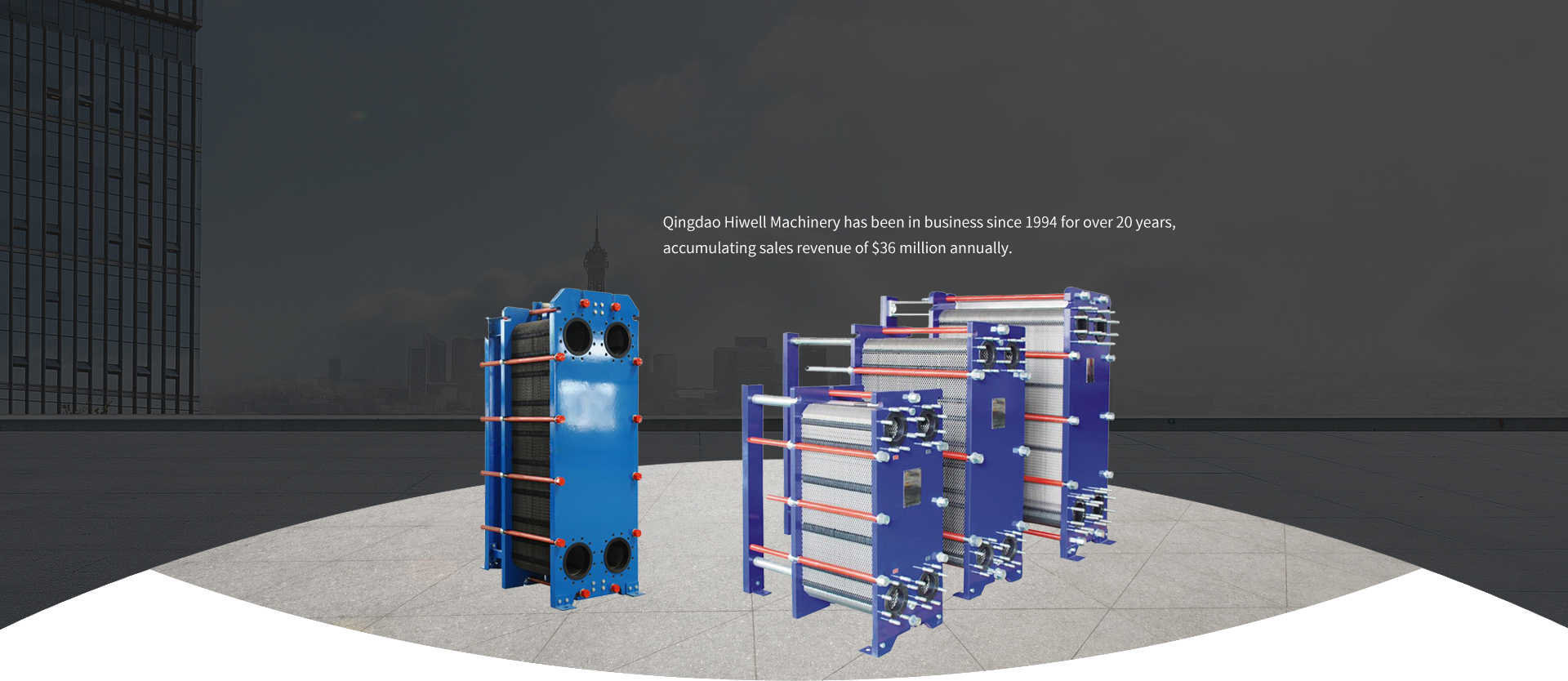

- Product Name: Fully welded plate heat exchanger

- Product Classification: Fully Welded PHE

- Company name: Qingdao Hiwell Machinery Co., Ltd.

- Contact Address: Room 2707 Zhaoyin Mansion, 36, Hongkong Middle Road, Qingdao 266071, China

- Add time: 21/01/04

Product Details

Product inquiry

· Why fully welded type?

· Fully welded plate heat exchanger has high heat transfer efficiency and small size. It is convenient to clean and require a small amount of maintenance. This design helps to save space and reduce your investment cost.

· Fully welded PHE has the advantages of both tube & shell and plate heat exchangers. And this makes it a good choice for the widest range of applications, especially suitable for the application in high temp, and high pressure industries such as metallurgy, oil refining, chemical industry, power plant and etc.

Our fully welded heat exchanger

. Include plate-frame type, plate-shell type, and wide channels plate type heat exchanger

. Pressure up to 60 bar, temperature up to 900℃

. Suitable for the difficult conditions

Our fully welded PHE convince with their heat transfer coefficient and relatively low investment cost. They are developed to meet the challenges of specific applications and give a good performance even in most difficult conditions.

Advantages

. Easy cleaning thanks to simple opening of the unit

. Fully welded plate pack

. High temperature and pressure resistance

. Low space requirements and easy to install

. Access from both media sides

. Operation under vacuum with lowest pressure loss