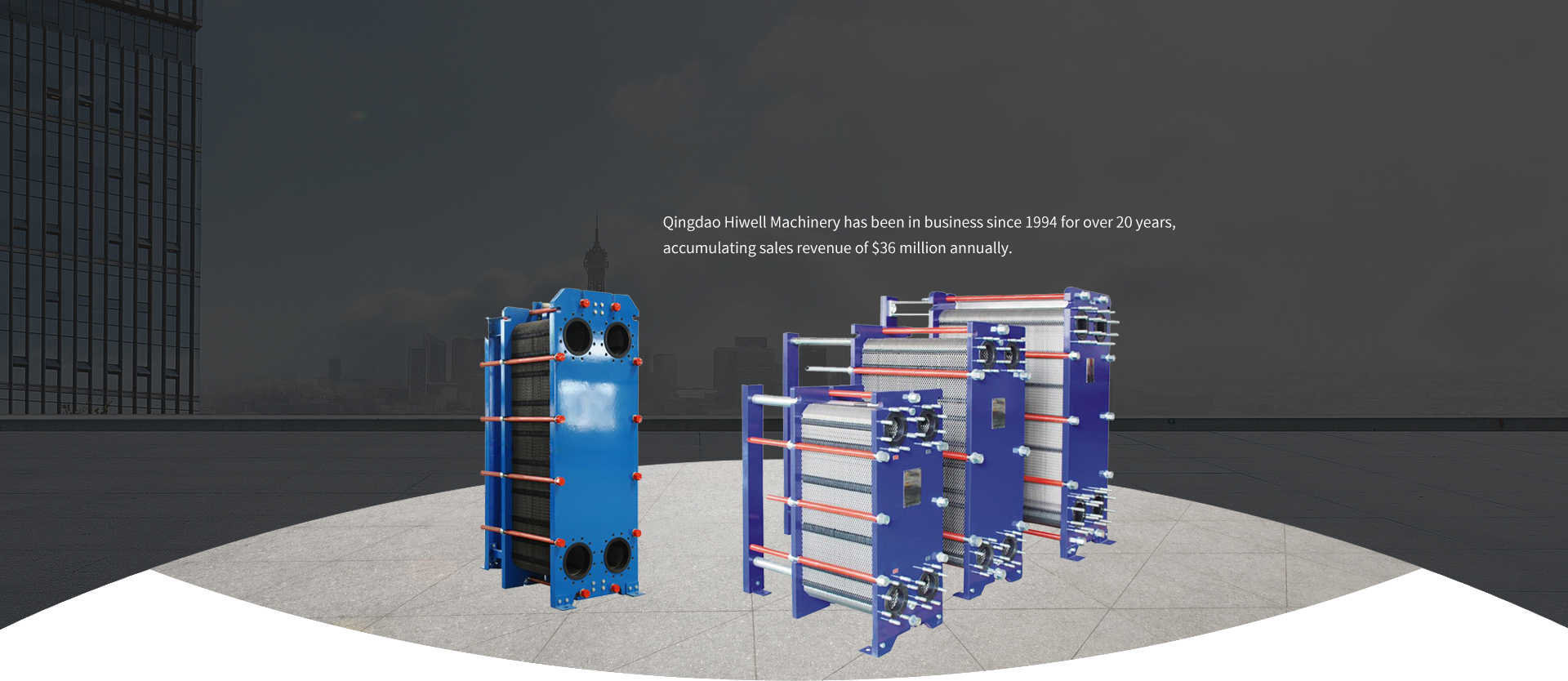

- Product Name: Gasketed Plate Heat Exchanger

- Product Classification: Gasketed PHE

- Company name: Qingdao Hiwell Machinery Co., Ltd.

- Contact Address: Room 2707 Zhaoyin Mansion, 36, Hongkong Middle Road, Qingdao 266071, China

- Add time: 21/01/04

Product Details

Product inquiry

· The heat exchanger is individually designed according to your requirements, and we also supply certain types. Our product range consists of gasketed plate heat exchanger, semi-welded heat exchanger, fully welded heat exchanger and tube& shell heat exchanger etc.

· This type of exchanger is the most efficient type of heat exchanger with its low cost, flexibility, easy maintenance, and high thermal transfer.

· The plate pack is assembled between a fix frame plate and a movable pressure plate and compressed by tightening bolts. The plates are fitted with a gasket which seals the interplate channel and directs the fluids into alternate channels. The number of plates is determined by the flow rate, physical properties of fluids, pressure drop and temperature program.

Key parameters of our gasketed plate heat exchanger

. ±0.1mm accuracy of groove.

. Maximum temperature can reach 180°C.

. Maximum working pressure can reach 25 bar.

. The diameter of porthole can reach 450mm.

Key Industries in which you may need our products

Food, dairy and beverages / Biofuels / Biotech and pharmaceuticals / Chemicals /Engine and transportation /

Hydrodynamic force / Industrial fermentation /Latex production / Machinery / Marine and diesel power /

Metals and minerals, extraction /Metal-working / Mining and Pigments / Oil and gas / Oil refinery / Power /

Pulp and paper / Refrigeration and cooling / Semi-conductor system /Sugar industry / Wastewater treatment

We also supply accessories. There are more than 100 plate and gasket types for your choice.

Plate material: SS304, SS316L, Titanium, Nickel, Hastelloy

Plate thickness: 0.5mm, 0.6mm, 0.7mm

Gasket material: NBR, EPDM, FPM, Silicone rubber

If you are interested in Gasketed Plate Heat Exchanger, and want to make an enquiry, please let us know the following information.

1. Medium.

2. Flow rates or heat load.

3. Inlet and outlet temperature.

4. Operating pressure.

5. Maximum allowable pressure drop.