- Product Name: Tube & shell heat exchanger

- Product Classification: Tube & shell heat exchanger

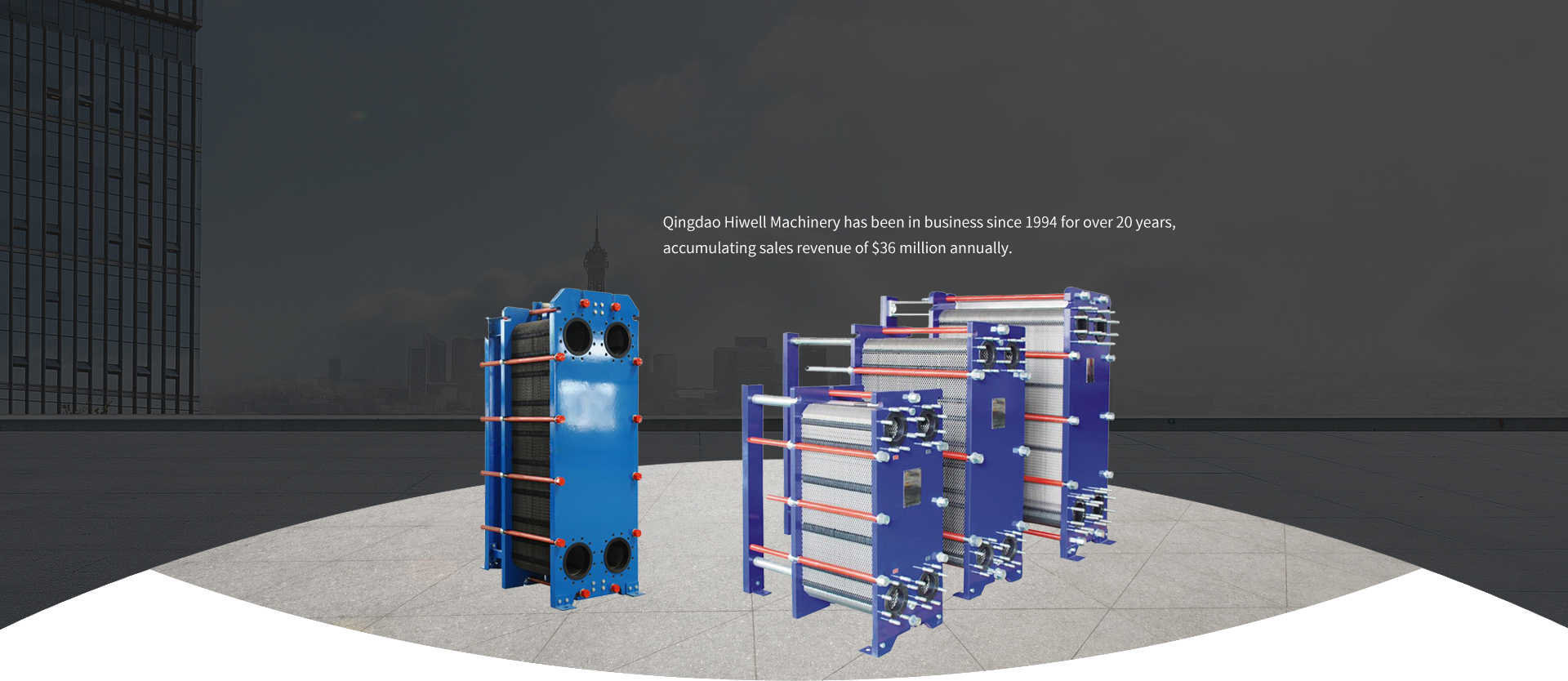

- Company name: Qingdao Hiwell Machinery Co., Ltd.

- Contact Address: Room 2707 Zhaoyin Mansion, 36, Hongkong Middle Road, Qingdao 266071, China

- Add time: 21/01/04

Product Details

Product inquiry

· Introduction

· Tube & shell heat exchangers are the most common type of heat exchangers. They are widely used in the chemical process industries. And in oil refining industry, metallurgy industry and power stations, they are also the essential equipment because of the numerous advantages over other types of heat exchangers. Our heat exchangers are designed individually to each application to suit the different needs in various industries.

· Now we mainly do OEM for air condition and refrigeration chiller manufactures. We have established long-term and stable relationships with tube material suppliers in China to ensure reliable and high quality production

Advantages of tube & shell heat exchangers

. Stationary, reliable and high quality design

. Optimum designs to each application

. High pressure and temperature resistance

. Ripe manufacturing process and operation

. Low investment, operating and maintenance costs relative to the service life

. Easy to clean

Our Advantages

. Professional team of technicians, sales, and maintenance

. Japanese style of management

. ASME certified

. Quality assurance

. Pressure test before delivery

Technical parameters (depending on design)

. Maximum design pressure: 10Mpa

. Maximum design temperature: 650℃

. Maximum shell diameter: φ2600mm

. Maximum heat transfer area of single unit: 4000㎡